Solutions For Reflow

Solutions For Reflow

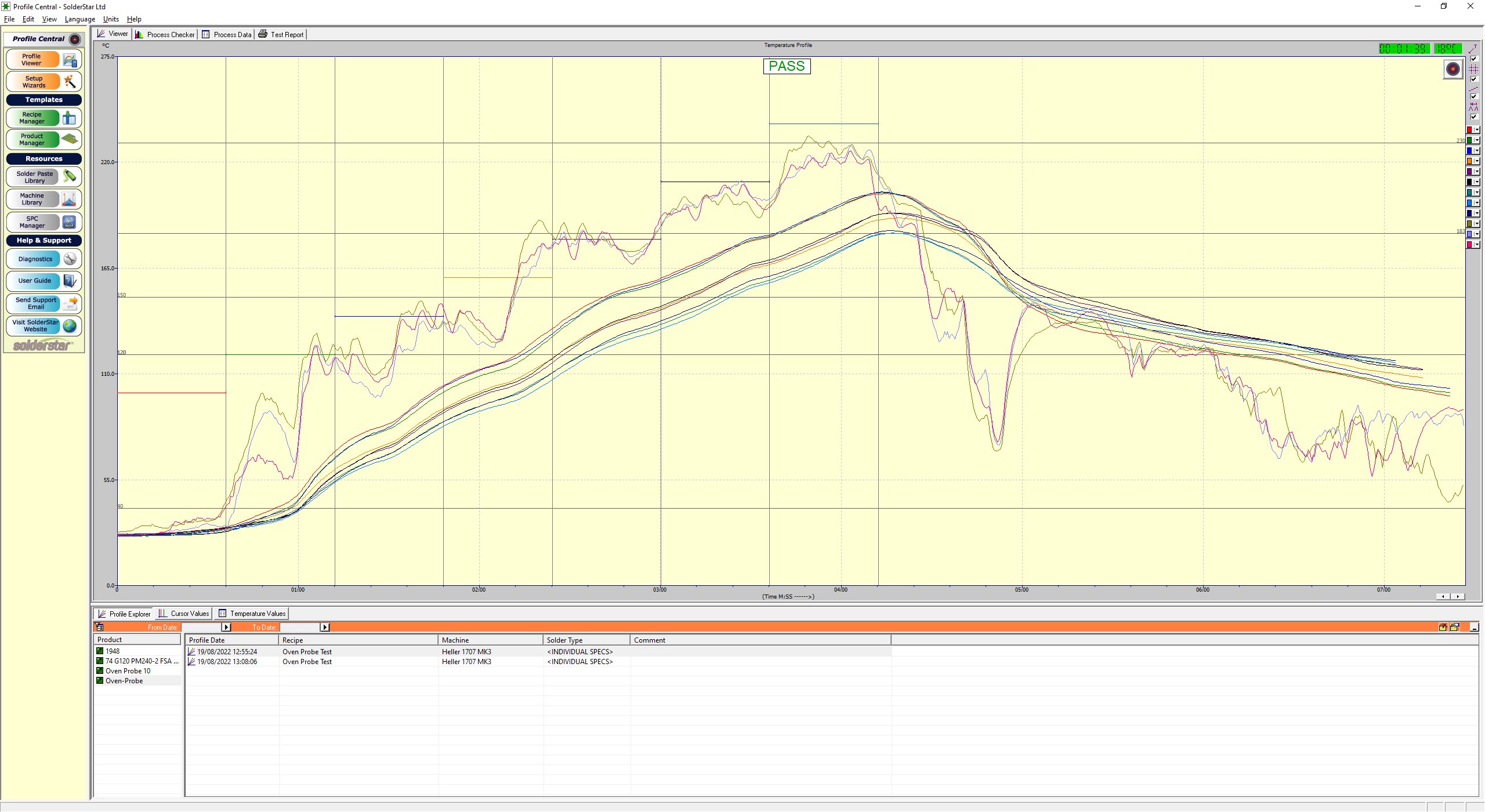

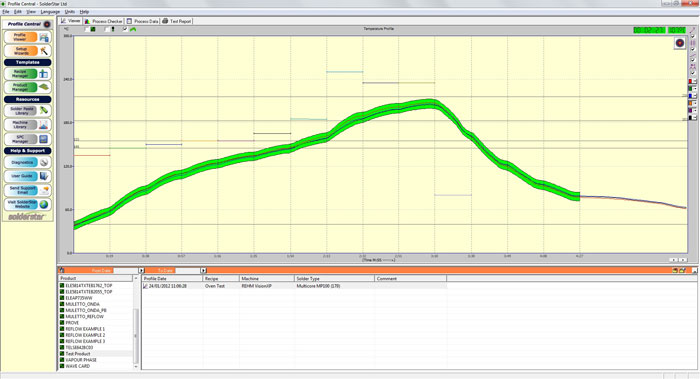

Instantly and accurately detect process changes due to variations in oven loading, convection levels, conveyor speed or zone set points errors.

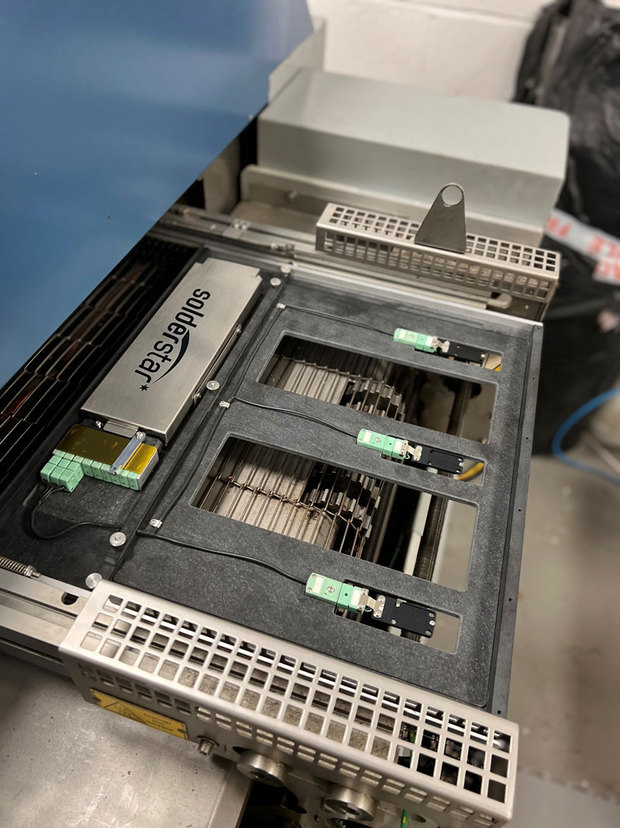

The SolderStar DeltaProbe is periodically passed through the reflow process to allow rapid verification of oven conditions against a stored baseline profile. Process change, due to variations in convection levels, conveyor speed or zone set-points, are instantly and accurately detected and the operator is notified visually through the PC analysis software. Integrated SPC tools allow the operator to produce process control charts for ongoing process control measurement, evaluation and corrective action.

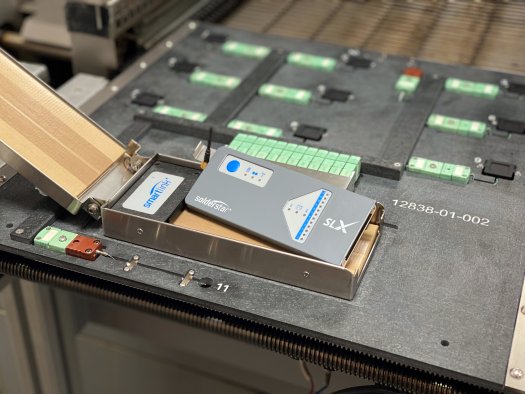

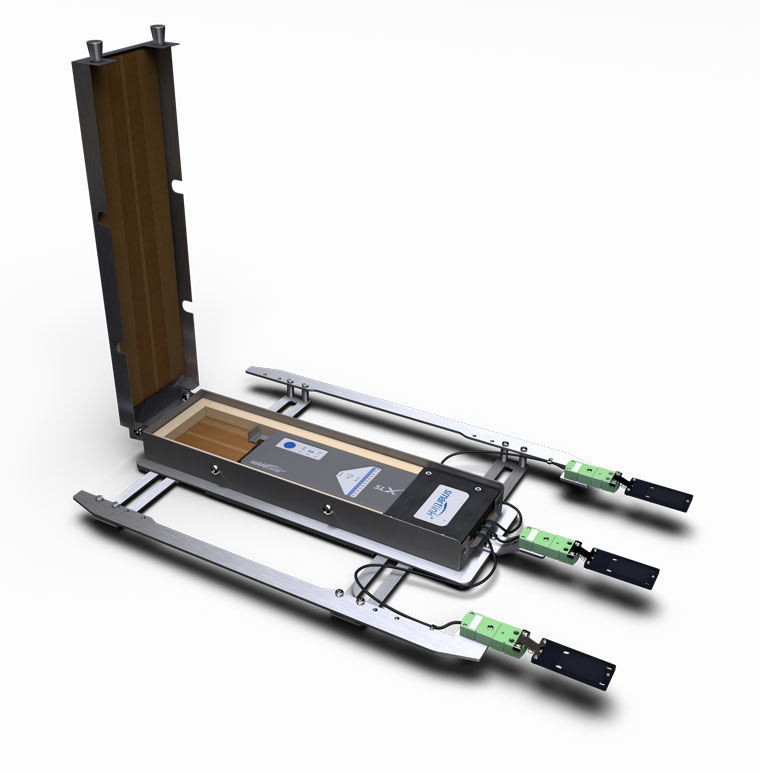

The DeltaProbe solution removes the need to use fragile test boards for periodic profiling required for ongoing control of the reflow process. Although profile setup requires a temperature profile to be captured from a real test PCB, ongoing periodic process monitoring can be achieved by measuring the difference from an established process baseline. The DeltaProbe device is passed periodically through the process to provide oven verification and ease SPC data capture.

With matched sensors and no test card or long trailing wires, the DeltaProbe streamlines the procedure of daily testing of the reflow process and generates highly repeatable oven measurements. It incorporates an adjustable carrier frame which can be set to the production conveyor width and can be used without any disruption to production flow.

Process change, due to variations in convection levels, conveyor speed or zone set-points, are instantly and accurately detected and the operator is notified visually. Integrated SPC tools allow the operator to produce process control charts for ongoing process control measurement, evaluation and corrective action.