Solutions For Reflow

Solutions For Reflow

Download the demo/latest versions of our profiling software by visiting our resource portal - Solderstar Central

At the heart of all Solderstar’s profiling solutions lies the powerful and intuitive Profile Central Software suite, regarded by many as the best available.

It has been designed to be user-friendly for both temperature profiling novices and experts alike. Industry terminology, coupled with our unique form of process parameter verification functions, allows users to quickly set up, optimise or verify their soldering processes. The software makes the next step, from a simple profiling tool to streamlining the capture and management of process control information from the shop floor.

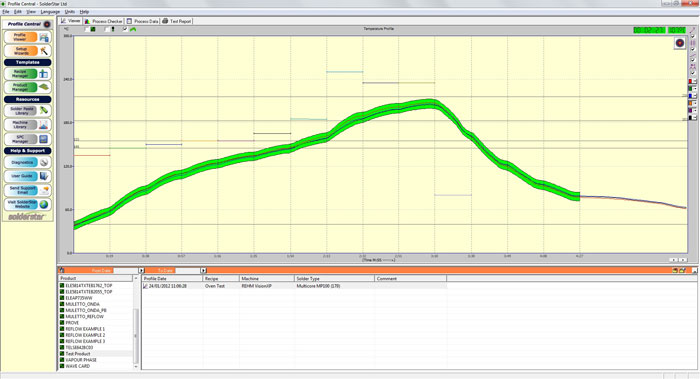

This simulation tools enables the user to make virtual changes to temperature and conveyor speed parameters and view the effects of those changes on the thermal profile and process. The procedure is offline so it does not impact real production; it is fast, as it eliminates real, trial-and-error procedures, and it is extremely easy to execute and understand, as SolderStar replaces the more conventional ‘tables of meaningless numbers’ with a graphical format that enables the user to see clearly whether changes improve or impair the process.

Profile Explorer automatically stores downloaded profiles against the user's product name, creating a chronological record of profiles for each product, allowing users to organise their profiles and providing process traceability.

Profile Viewer allows any profile in the database to be viewed instantly.

Profiles can be measured, annotated, or downloaded into professional, comprehensive reports in hardcopy or digital format.

Profile Checker takes downloaded profiles and automatically calculates the process parameters of interest, plotting them against solder paste process limits to illustrate how well each of the process parameters is centred on the appropriate process window. The entire process is evaluated on a single, easy-to-understand visual that displays good(green)/bad(red) results.

For every product manufactured, Product Manager records and manages profiling parameters including test card details, datalogger settings and sensor attachment points, facilitating future process set-up.

The integrated machine and solder paste libraries includes many of the most common data required for production. By selecting their data from the library, users automatically analyse their soldering process using predefined templates for common solder pastes or oven type.

Professional, configurable test reports and process documentation can be generated at the click of a mouse. Reports on products, recipes and machine settings, temperature profiles and process checker graphs can be printed out or emailed.

Process trends can be monitored and process yields and quality can be improved through continuous SPC. Using SPC Manager, users can evaluate process trends for profiles selected from the database, illustrating these on professional Xbar and Range charts that include Cp, Cpk and control limits. Charts can be output in hard copy or digital format.

Profile central has many software help wizards to walk you through common task, from simply adding a new machine to a complete walkthrough of profiling operations.