Solutions For Reflow

Solutions For Reflow

Process measurement shuttles provide the platform for advanced and repeatable machine verification, each shuttle features the Smartlink system to quickly connect your SLX datalogger. Advanced parameters such as conveyor vibration, reflow vacuum level and oxygen PPM are measured alongside standard temperature profiles.

The new O2 Reflow Shuttle provides zone by zone analysis of oxygen levels throughout the reflow process. Issues with nitrogen leakage throughout the oven are pin-pointed as the device captures and displays the oxygen PPM level alongside the oven zone diagram and temperature profile.

The reflow shuttle is fitted with an array of sensors for independent measurement of advanced process parameters required for modern reflow soldering applications. Temperature profile verification is achieved with an array of type-K sensors arranged to measure top and bottom heater performance. At the front of the shuttle are matched temperature sensors which provide information regarding uniformity of heating across the width of the heated zone.

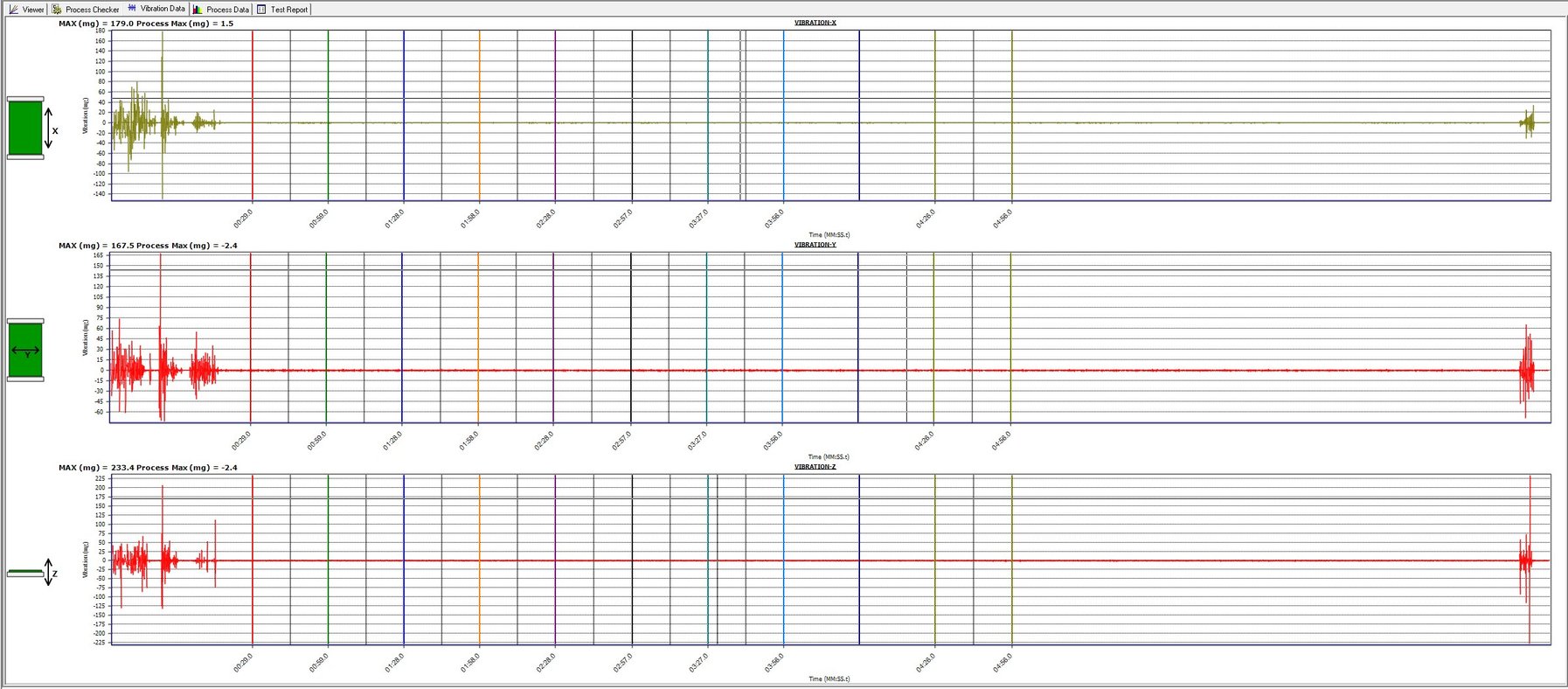

Process vibration measurement is a requirement for many manufacturers, to establish a baseline of acceptable levels in all 3-axis within the machine. Data captured can allow the engineer to see the effect of fan speed settings on vibration/harmonics in the process, along with detection of changes in vibration levels due to issues with the machine conveyor or extraction system.

Where a vacuum stage is added to the reflow process, an optional measurement module is fitted to the reflow shuttle allowing verification of vacuum levels down to 10 mbar. Vacuum profiles are captured and displayed as an overlay with the PCB temperature profile. Hold time below a desired level vacuum level, pull down and release rates are calculated - essential for ensuring that component shift does not occurs.